Few images of summer being ushered in are as iconic as dear old dad or grandpa sitting on the porch with a cold beer in his hand. It’s likely that beer came from one of the Big 3 in the industry: Budweiser, Coors, or Miller. There’s little chance your pops was making his own beer in his kitchen or garage.

My how times have changed though. Since homebrewing laws have relaxed in the last decade or two (before that they were rather stringent — reducing homebrewing to an underground hobby), small batch craft beer as a whole has enjoyed enormous growth, both in the commercial and DIY realms. With an investment of about 100 bucks, you can get all the equipment you need to make great beer at home, and that equipment should last many years. And for about $50 (and often less), you can buy all the ingredients you need to make about 50 bottles of beer, which comes to much less per bottle than you’d normally pay for a high-quality brew.

Today, I’ll take you through the types of homebrewing, supplies and ingredients needed, as well as a general outline of the steps and principles of making good beer from a kit. Let’s get started!

There are a few tiers of brewing that differentiate the occasional brewer from the true hobbyist. Using kits is the starter tier. You have everything provided for you in a handy-dandy box — malt extract, yeast, hops, even bottle caps. You’re also provided a step-by-step recipe that makes it pretty darn easy to achieve a drinkable and enjoyable bottle of beer. (If you aren’t familiar with the general process of how grains are turned into beer, here is a great and quick guide as to how it works.)

As skills, tastes, and budget increase, a homebrewer can work their way up and produce higher-quality beers. You’ll end up creating your own recipes, mashing your own grains, and generally having more control over the process. With beer from a kit, you’re basically combining ingredients on the stove in a certain order, maintaining cleanliness, and ensuring that directions are followed. To be honest, there’s not much creativity involved.

But, that’s okay at first. When I asked Aaron Holstad and Branden Miller of Black Shirt Brewing about which type of homebrewing the beginner should pursue, they unequivocally said one should go with kits unless they’re ready to invest more money and time into their hobby and become true amateur at-home brewers.

So there ya go. Straight from the horse’s mouth. While it might feel a little like cheating to brew from a kit that has everything pre-measured and ready for you, it provides a great way to get started brewing, and gives you a feel for the steps necessary. If it’s something you’ll only do once a year or so (like me), you’ll be hard-pressed to find it worth it to invest in more than just your basic supplies. And if you decide you love it, and want more creativity and control, then you can decide to take things up a notch.

In this article, I won’t be providing super detailed step-by-step instructions, but more general guidelines for coming out with a great batch of beer. Why is that? Every kit you buy is unique, and has slightly different ingredients, brew times, etc. Use my principles, then rigorously follow the recipe/directions that came with your kit.

If you’re wondering why you need an article on how to make beer from a kit, if it already comes with directions, know that while the kit simplifies and streamlines the brewing process, there are still sticky points the first time you try it. While the first batch of homebrew I made a few years ago was okay, I was pretty clueless about the whole operation. I didn’t really understand what the various supplies were for, I didn’t understand the process enough to know how to troubleshoot any issues, and I wasn’t even sure what my beer was supposed to look like in a few of the steps. I’ve gained a bit more experience over the years, and I’ve also had a chance to talk to some professional brewers about the most important homebrew principles, as well as a couple ways the amateur should deviate from a kit’s directions to really get a great beer. In understanding all the supplies and processes behind kit brewing, you’ll be better able to handle any problem and have a better chance of creating a beer that’s worthy of sharing.

All these supplies are readily available in kits that you can get from any local homebrew store (which have become more common in big cities), or on Amazon. You can buy the things piecemeal, but the price wouldn’t be much different. The only things in the list below that you often won’t find in a kit are the brew kettle, thermometer, and hydrometer.

Your brewing can generally be broken down into two primary steps: brewing and bottling. Brewing takes place on the stovetop in a big kettle, and it’s then placed into a 5-gallon bucket (often fancily called a “fermentor”) to let the yeast do its thing and turn your liquid into an alcoholic beverage over the course of a week or two. The next step is bottling. Here you transfer your beer into a bottling bucket (yet another 5-gallon bucket, but with a spigot assembly), fill 12 oz bottles with the stuff, and then let that sit for a couple weeks to carbonate (or “bottle condition”).

In that light, I’ve broken supplies, and tips, into separate sections.

As noted above, every kit is unique. While the base ingredients are all the same — malt extract, hops, sometimes grains and maltodextrin (which is basically a sweetener) — the amounts, techniques, order of steps, etc. are not standardized. So below I’ll walk you through a general outline of how things go both on brew day and bottling day, but again, follow the directions that come with your kit. Those will be more helpful for your specific batch.

Plan on devoting 3-4 hours of your time on brew day, and then a week or two later, another 2-3 hours for bottling.

Here’s the stout kit I used. It has liquid malt extract (LME), dry malt extract (DME), grains, maltodextrin, and 2 packets of hops.

Before you get to brew day, crack open your ingredient kit and instructions and make sure you understand everything before diving in to cooking it all up. The ingredients you’ll generally see:

There are volumes dedicated to homebrewing and yeast (of which I’ve not read), but I’ll try to simplify things for our purposes. Yeast is what turns your liquid (or wort) into beer. It creates alcohol by converting sugar (found in your extract) into both CO2 and ethanol — or alcohol. At the most basic level, it’s that simple.

So of course your beer kit comes with a packet of yeast. The problem is that yeast is a finicky organism. It needs to be really fresh to do its thing — the fresher the better. When you walk into a homebrew store, the yeast is refrigerated. Freshness galore! With a kit though, while it may have been refrigerated before being shipped, you just never know. Jim Koch, founder and brewer of Sam Adams beer had this to say when I asked him about the yeast found in kits:

“Yeast is a living organism. In a homebrew store and at our brewery you’ll find it refrigerated and used within a specific timeframe. In a homebrew kit, the yeast may have been under heat and packaged for a very long time, which is not ideal. If it’s not cared for correctly, it won’t do its job.”

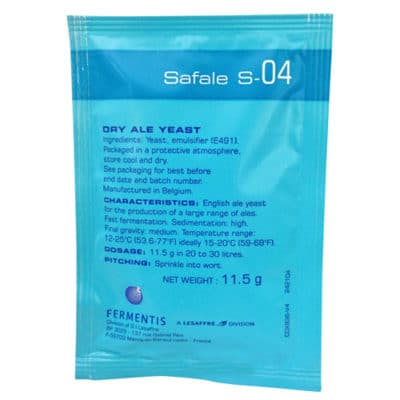

It’s always just a safe bet to ditch the yeast that came with the kit, and go get yourself some fresh stuff from the homebrew store. (If that’s an option, of course. Sometimes it isn’t, and that’s okay. I’ve made good beer with the yeast that came in a kit.) Ask the proprietor (or a homebrew forum) what type of yeast they recommend and how much. My latest kit came with a single packet, but the homebrew store fella told me to use 1.5-2 packets since I was making an imperial brew (imperial = more alcohol; more yeast = more alcohol).

If you have questions about yeast, the internet is your friend. There are homebrew forums galore, and plenty of guys who’d be willing to help out a newbie in need.

Koch told me this was the single most important step in making great beer:

“Always be a fanatic when it comes to sanitizing your equipment. Cleanliness is next to godliness. Nothing will ruin a homebrew quicker than brewing equipment that’s not properly sanitized or a bottle that’s not entirely clean.”

Clean equipment is your number one priority when brewing. If any germs or bacteria get into your wort, your beer will be fouled beyond repair. It’ll become sour, and not in the trendy way.

Every piece of equipment that touches your ingredients needs to be sanitized — kettle, buckets, all plastic tubing parts, all your bottles, bottle caps, stirring spoons, etc.

Be wary of any scratches in your equipment. Bacteria can make their home in scratches, and as Aaron and Branden from Black Shirt told me, it would take cleaning supplies that can’t be legally bought by home consumers to get it out. If something is scratched, best to replace it. (This also means you need to be careful with your equipment!)

Many folks will think of a bleach solution rather than buying a specialty brewing sanitizer; that can be okay, but bleach can seep into plastic’s pores, leading to off flavors in your beer. Best to use a cleaner made for homebrewing.

Beyond cleaning at the start of brew day (and bottling day!), make sure to clean your equipment again when you’re all done, just so things don’t get gunked up and extra dirty before you brew again. Sanitizing isn’t necessary at the end; a good soapy wipe down will do the trick.

In any recipe, you’ll start by boiling a large amount of water — 2-3 gallons. This takes a long time to do, so be patient. We’re talking 30-45 minutes depending on your heat source — on the longer end if using an electric stove. When your water comes to a boil, you’ll add your ingredients. (In some recipes, you’ll steep grains before you hit boiling — to repeat, your recipe is king.)

When you have a decent slow-rolling boil going, you’ll add your ingredients. Depending on your recipe, you’ll add things all at once or in increments. You’ll have things going in a slow boil for 1-2 hours before transferring the liquid into your fermentor bucket. Feel free to give it a taste at this point. It’s fun to see how it transforms into beer over the course of a few steps and a couple weeks!

After the time specified by your recipe, you’ll pour your wort into your sanitized fermentor bucket, along with fresh water that will get the total amount of liquid to 5 gallons. Before doing so though, you’ll often cool that wort, as it needs to be below 80 degrees F in order to add your yeast (called “pitching”). This can be done with a combination of an ice bath for your brew kettle, adding cold water to the fermentor bucket, and using a device called a wort chiller. When I brew, I put the kettle into an ice bath in the sink for 10-15 minutes, pour it into the fermentor bucket, and add cool water. That usually gets me in the right range to add the yeast.

Once you’ve done that, you’ll pop the lid and airlock on, then put the bucket in a cool place for a week or two. Refer to your instructions for how to tell if your brew-in-the-making is healthy (usually means seeing bubbles in the airlock within 24-48 hours, and for a period of time after that).

See above. Bottles, caps, all tubing, etc.

This is what your brew will look like when you crack the lid after a week or two. Don’t worry, that’s just dead yeast (a good thing). It first congregates at the top to get its work done, then largely settles at the bottom. Some of it remains floating at the top though. The first time I brewed, this scene freaked me out — I thought my beer was done for!

Crack open your fermentor bucket, and don’t be alarmed. See the above photo and caption. Hoist the bucket up onto a countertop, and using your racking cane and tubing, transfer the beer to your bottling bucket. (The racking cane is pumped in order to begin the siphoning.) The built-in filter on the racking cane keeps the muck from getting into the bottling bucket.

Transferring beer to the bottling bucket.

What’s left at the bottom of your fermentor bucket. It looks gross — it’s just dead yeast. A good sign. Don’t dump this in your kitchen sink — out in the yard is fine.

Spigot with plastic tubing attached, and bottle filler attached at the end. The little black tip, when pressed to the bottom of a bottle, releases beer into the glass.

Attach your tubing and bottle filler, and get to work loading up your bottles with that tasty brew! Have towels handy (either cloth or paper), as this step can get a little messy.

Don’t worry, I’m still married, I just don’t wear my ring when brewing.

After filling 50-60 bottles or so, use your handy dandy capper to seal each bottle for conditioning (remember, that’s how your beer is carbonated). Store your freshly bottled and capped beer in a cool place for about two weeks, and you’ll be all set with a delicious, homemade beverage!

Both Koch and the Black Shirt guys said this step was just as important as any other if you truly want to make good beer. If something is off in your beverage, you’ll have virtually no way of knowing why without the experience of other brewers providing you feedback. I’ve made a batch of beer that just didn’t taste good, and since I didn’t share it with any other homebrewers, to this day I don’t know what happened or what could have corrected it.

And even if your beer is good, you won’t really know how to make it better on your own. I’ve had this experience as well, making some batches of good beer, but not really great beer.

Our nation (and world) is filled with homebrew clubs that are eager to try your brew and offer helpful criticisms. As Koch told me, “find your Yoda.” They’re a forgiving group of people because they’ve made all the same mistakes you have.

Part of the fun of homebrewing is sharing your creation with friends and family. Bring a six-pack to a dinner party as a gift for the host, contribute a case to a holiday BBQ, and invite your neighbors to taste and critique your brew. Beer is best enjoyed with friends, and doubly so when it’s homemade!

Big thanks to Jim Koch, founder of Boston Beer Co. — the legendary founder and brewer of Sam Adams beer — as well as Aaron Holstad and Branden Miller at Black Shirt Brewing here in Denver, for their help and guidance with this article.

The Complete Joy of Homebrewing by Charlie Papazian — Jim Koch’s bible and go-to resource